Who We Are

At Oktober Design, we craft precision canning equipment that meets the demands of professional beverage producers and serious small-batch operators alike. From our earliest sketches to a growing product ecosystem, we’ve focused on practical innovation and equipment that actually works in real production environments.

Our team began with three mechanical engineers, bringing years of experience designing precision machines for the aerospace industry. That background shows up in everything we build: robust construction, serviceable design, and zero tolerance for gimmicks.

This year marks a major milestone with the release of the CL1 - Full Automated Canning Line. Running at 20 cans per minute, CL1 delivers affordable, compact automation for producers ready to scale. Supporting systems including our depalletizer, conveyors, filler, and additional automation modules are now available or actively rolling out, creating a complete, modular canning line built specifically for craft beverage production.

Alongside the line, our Oktober Depalletizer simplifies full-height pallet handling with a smart, layer-by-layer design that avoids bulky overhead structures. And our trusted Model 8 Automatic Can Seamer continues to provide reliable, consistent seams for on-demand and production canning alike.

Beyond equipment, we simplify can sourcing with custom pre-labeled cans, brite cans, and flexible ordering options, all backed by real human support. We source and build locally in West Michigan whenever possible, while our Sparks, Nevada facility helps reduce shipping time and cost for West Coast customers. Since launching online sales in 2016, we’ve grown through customer referrals, long-term relationships, and a commitment to building things the right way.

Whether you’re scaling up or just getting started, we’re here to help you can with confidence. Our team would love to hear from you!

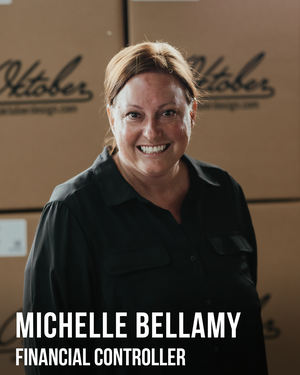

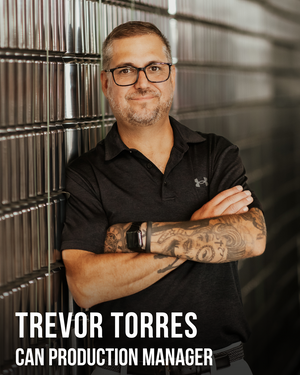

meet the team